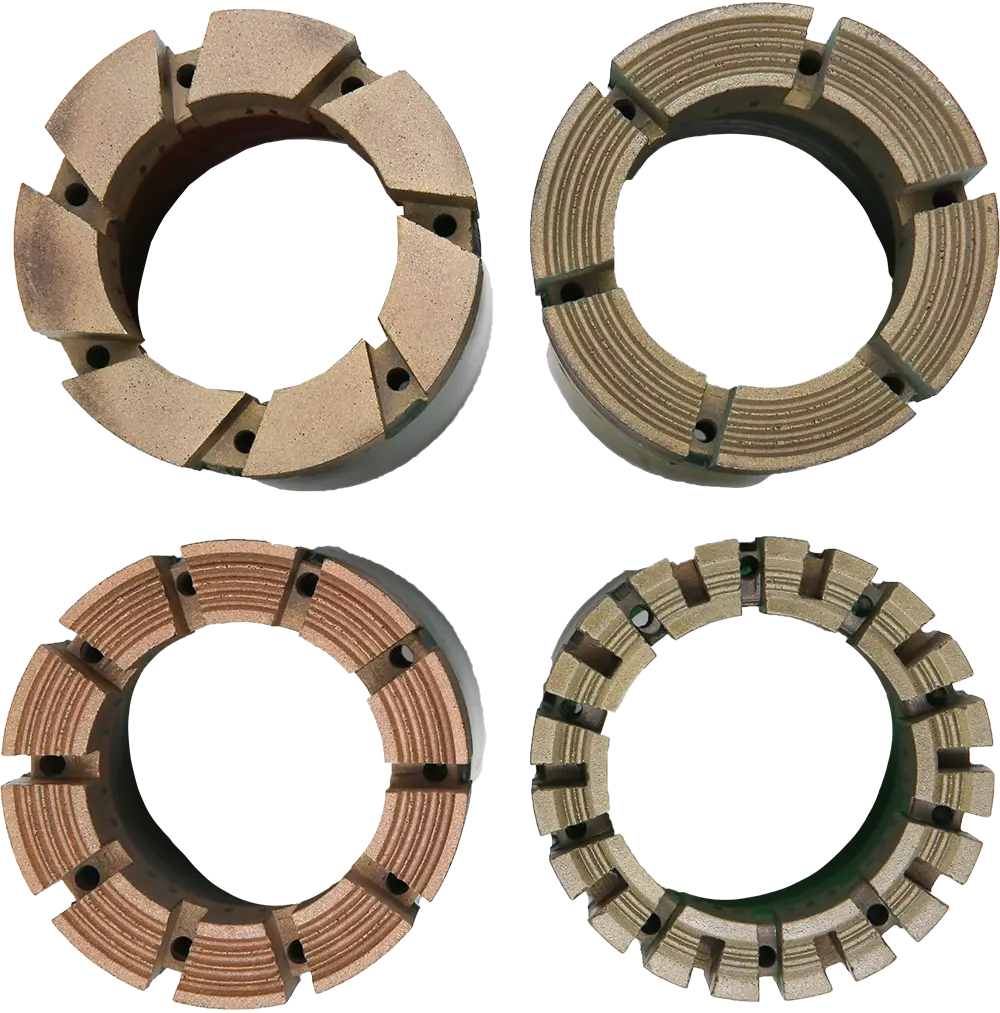

Drill bits from the Classic Range are the most popular choice due to their versatility across various formations. They feature a waterway width ranging from 5 to 8 mm, allowing drill fluids to circulate from the inside to the outside of the bits

After two decades of research and testing, a series of special bit matrix have been designed and developed to adapt to different geological conditions.

Various alloys are produced using advanced pre-alloyed powdered technology at Fastar’s manufacturing plant. The formulation of the bit matrix is managed by an industrial computer system that meticulously controls and monitors the entire process. The unique matrix composition is characterised by a strong chemical bond with diamond grains after sintering. This bond ensures rapid penetration and prevents the diamonds from detaching. As a result, our drill bits offer exceptional efficiency and an extended lifespan during drilling operations.